Features

Why Solimar Aeration Systems?

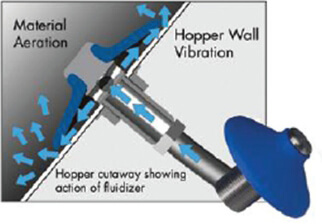

• Superior sealing properties at the outer edge of the aerator rubber stop the back flow of product into aeration lines even when flood loading.

• Optimized air volume unloads your silo or trailer faster. Too much air moves more air than product.

• Original durable design will not crack, wear prematurely or clog like fabric pads. Carbon, stainless or aluminium models in a variety of sizes provide high volume, low pressure, or low volume, high pressure aeration.

• F.D.A. approved materials with operating temperatures up to 450ºF (230ºC).

• Direct replacement with improved performance for Fruehauf, Heil, Polar or Sure Seal aerators.

• Longer warranty than any competitor.

• Thousands of parts always in stock for on-time delivery

Insist on genuine Solimar disks with the trademarked Radial Ridge Design.

Nothing unloads faster, or lasts longer than Solimar.